Welcome to the fascinating City of Elmina, a hidden gem nestled along the enchanting coast of Malaysia. With its rich historical heritage, vibrant culture, and breathtaking landscapes, Elmina offers an unforgettable experience for both local and international travelers. In this article, we will delve into the advantages, importance, and usage of exploring this remarkable city,… Continue reading Discovering the Enchanting City of Elmina: An Ideal Destination for Malaysians

Tag: malaysia

Preserving Freshness, Reducing Waste: The Art of Food Packaging

Food packaging plays a crucial role in preserving the freshness of products while minimizing waste. Malaysians, like people around the world, are increasingly concerned about the quality and sustainability of the food they consume. In this article, we will explore the art of food packaging such as tupperware malaysia, discussing its importance in maximizing freshness,… Continue reading Preserving Freshness, Reducing Waste: The Art of Food Packaging

Enhancing Construction Efficiency: Scaffolding in Malaysia

When it comes to construction projects in Malaysia, scaffolding plays a vital role in ensuring safety, efficiency, and productivity. Scaffolding serves as a temporary structure that provides a stable platform for workers to perform tasks at various heights. This article explores the importance, advantages, and benefits of scaffolding Malaysia. The Importance of Scaffolding in Construction… Continue reading Enhancing Construction Efficiency: Scaffolding in Malaysia

Future of Wax Emulsion Industry in Malaysia

Wax emulsion is a widely used material in the manufacturing of various products in Malaysia. The emulsion is used as a coating material for various surfaces, including paper, textiles, and wood. Wax emulsions are made of wax, water, and emulsifiers, which help to stabilize the mixture. The product is available in different types, including paraffin… Continue reading Future of Wax Emulsion Industry in Malaysia

Choosing the Right Laboratory Balance or Scale

Are you a Malaysian working in a laboratory or interested in conducting experiments at home? If so, you know that having the right equipment is essential for accurate and reliable results. When it comes to measuring mass or weight, laboratory balances and scales are critical tools. However, not all balances and scales are created equal,… Continue reading Choosing the Right Laboratory Balance or Scale

Premium Baby Toothbrushes for Healthy Teeth: Shop for Quality Malaysian Toothbrushes for Your Little One

Malaysian toothbrushes for babies are specifically designed to provide the highest level of oral care for the little ones. They come with soft bristles and rounded heads that help clean teeth and gums gently while being gentle on delicate skin. The handles are also ergonomically designed to make brushing easier for parents and children alike.… Continue reading Premium Baby Toothbrushes for Healthy Teeth: Shop for Quality Malaysian Toothbrushes for Your Little One

Explore Malaysia’s Fantastic Range of New Mother Products: From Nursing Essentials to Baby Gear and More!

There is a wide range of new mother products available in Malaysia, from nursing essentials to baby gear and more. Nursing essentials include breast pumps, bottles, sterilizers, nipple shields, and shields for breastfeeding babies. Baby gear includes strollers, car seats, bouncers, swings, play mats, and other items that make parenting easier. There are also a… Continue reading Explore Malaysia’s Fantastic Range of New Mother Products: From Nursing Essentials to Baby Gear and More!

Looking for insurance plans for young adults Malaysia? AmMetLife

There are many types of insurance in the world and many offers that will be at insurance companies. Just need to looking for insurance plans for young adults Malaysia. This is one of the insurance plans that really gives good things for young adults. It was really recommended for them to looking for insurance plans… Continue reading Looking for insurance plans for young adults Malaysia? AmMetLife

Three Parts Of Fitness That Have To Do With Health

Bidang perubatan – The three fitness elements all have a role in overall fitness and serve as guidelines for improving one’s fitness levels. Physical activity has obvious benefits, which you are well aware of. The key is to define fitness accurately and know how to get there. The five facets of fitness are intended… Continue reading Three Parts Of Fitness That Have To Do With Health

The Four Procedures For Establishing A Laboratory

Anyone who has tried to set up a lab before knows that it is not easy, especially if you are starting from scratch. But if you work out the details and understand the small stuff, you can make it easy with the help of a good company that expert in lab installation Malaysia. Don’t… Continue reading The Four Procedures For Establishing A Laboratory

Unleashing the Power of Social Media Marketing for Cafes

As a cafe owner, it’s important to stay up-to-date on the latest marketing strategies like using cafe pos system Malaysia in order to increase your business. Traditional methods like flyers and discount coupons can still be effective, but if you really want to get ahead of the competition, then leveraging digital platforms is key. Social… Continue reading Unleashing the Power of Social Media Marketing for Cafes

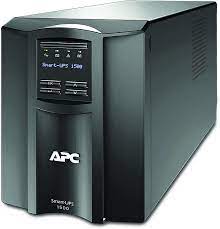

What is a power UPS Malaysia

A power UPS, or uninterruptible power supply, is a device that provides a backup power source to critical systems in the event of a power outage or other disruption to the main power source. It is commonly used in a variety of settings, including data centers, hospitals, and other critical infrastructure. If you need a… Continue reading What is a power UPS Malaysia

Single person? Better get Vios GR Sport Malaysia now!

There were many types of cars that were released in this world and also in Malaysia had many brand cars that entered Malaysia’s markets. One of the best cars is Vios GR Sport Malaysia. It was the best for the single person. Why was it for a single person? Better they had this as their… Continue reading Single person? Better get Vios GR Sport Malaysia now!

What is wax emulsion Malaysia

Wax emulsion Malaysia is a special material that is often used in industry. There is a lot of information about wax emulsion on the market. It can be very difficult to identify whether this information is true or not. So in this article I will provide you with some information on everything you need to… Continue reading What is wax emulsion Malaysia

What You Need To Know Before Choosing A Science Foundation Course

Choosing the right science foundation course is an important decision for students interested in study in science in Ireland. The Science Foundation Course at RCSI & UCD University is designed to give students the opportunity to study a range of science disciplines, and to prepare them for entry into undergraduate courses in the area. In… Continue reading What You Need To Know Before Choosing A Science Foundation Course

Enjoys Online Shopping? Read This!

Online banking has been around since the internet first hit mainstream use, and it’s made managing your finances infinitely easier. From securely transferring funds between accounts to setting up direct payments for bills and services, internet banking can save you time, money, and effort. But internet banking isn’t only about managing your own finances; it’s… Continue reading Enjoys Online Shopping? Read This!

Best bunkering service Malaysia, you need to know !

As we know bunkering service is used just for ships because it will bunkering it to supply the oil for the ships. The ships need to know the best bunkering service Malaysia, for the future they will use it. Must be smart in choosing the best bunkering service Malaysia, one of the best is Altus… Continue reading Best bunkering service Malaysia, you need to know !

Eco Friendly Tiffin Set Malaysia: Use Tiffin For Food Safety

Eco friendly tiffin set Malaysia are widely used nowadays. Tiffin has come to mean lunchbox in modern usage. Today’s tiffin come in a wide variety of sizes and forms, but they are typically spherical with three or four stainless steel stacking compartments that are sealed snugly with tight lids, as well as side clips and… Continue reading Eco Friendly Tiffin Set Malaysia: Use Tiffin For Food Safety

Selecting the Right POS System for Small Businesses

Point-of-sale (POS) systems are essential to running a business well. A POS system, specifically ipad pos system Malaysia, should make it easy and safe to accept and process different types of payments. You’ve come to the right place if you need a POS system for a small retail or restaurant business. A POS system can… Continue reading Selecting the Right POS System for Small Businesses

Medical Course: Is It Good?

Medical courses are indeed one of the most wanted and a great field that have been dreamt by students in Malaysia, and probably by parents too. It is beyond doubt how it is something that people would look up to for the sake of a good future, other than engineering, law and many more. This… Continue reading Medical Course: Is It Good?